How To Select The Type Of Valve Limit Switch Box?

In the field of industrial process automation, the selection of valve limit switches is crucial. It not only affects the normal operation of the equipment but also directly relates to productivity and safety. However, faced with a wide range of products on the market, many engineers and purchasers feel at a loss. The valve limit switch, as an important position feedback device, can convert the position status of the valve into an electrical signal to realize remote monitoring and control.

For manual valves

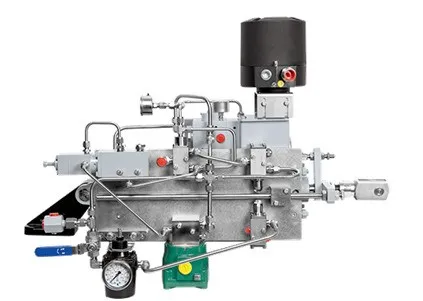

For rack and pinion pneumatic actuators

For pneumatic control valves

For scotch yoke pneumatic actuator

For long-stroke pneumatic actuators

The Basic principle of Valve Limit Switch Box

First, we need to understand the working principle of the valve limit switch. It does so by detecting the position of the valve, and when a predetermined position is reached, a signal is sent to control the valve action. Therefore, when selecting a limit switch, it is important to ensure that it matches the type of valve and its operating principle.

Use Environment of Valve Limit Switch Box

Different working conditions and environments have different requirements for valve limit switches. For example, some occasions may require limit switches with explosion-proof, waterproof, dustproof, and corrosion-resistant properties. In addition, it is also necessary to consider the impact of temperature, humidity, vibration, and other factors on the limit switch.

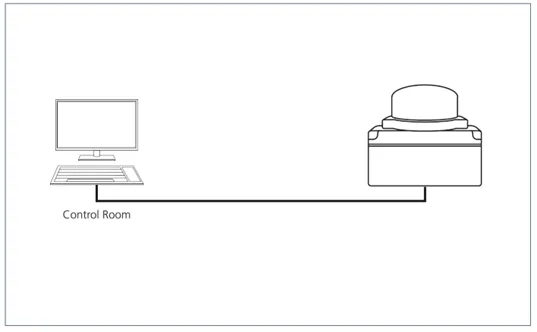

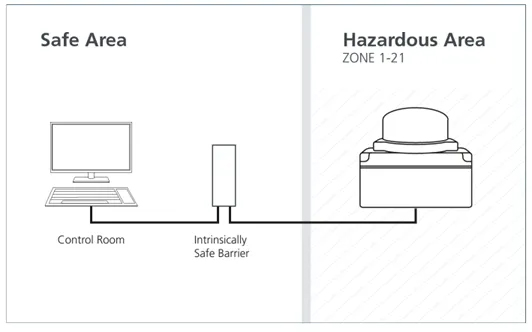

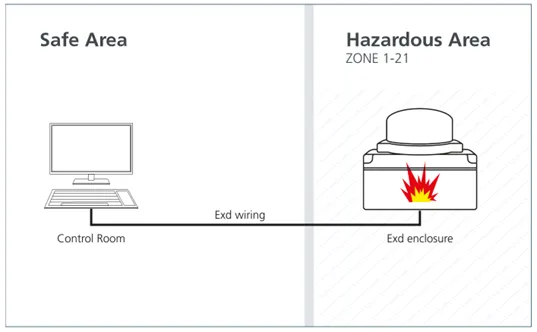

Valve limit switches can be categorized into non-explosion-proof, intrinsically safe explosion-proof, and explosion-proof types according to the use environment.

Non-Explosion-Proof

Intrinsically Safe Explosion-Proof

Explosion-Proof

How to Select Limit Switch Box?

Mechanical valve limit switch

Mechanical valve limit switch is the most common type, by physically pressing the microswitch, switching the switch state to sense the position change of the valve. When the valve reaches the set position, the mechanical contact closes or breaks, thus triggering the signal.

Typical expression: “knife” Pole and “throw” Throw, mechanical limit switches are divided into single-knife single-throw – SPST, single-knife double-throw – SPDT, double-knife double-throw – DPDT, three types, the most common in the project is a single-knife double-throw The most common type in engineering is the single-pole double-throw SPDT.

Single-pole double-throw SPDT

Double-knife double-throw-DPDT

Mechanical valve limit switches are simple in structure, easy to install, and suitable for most valve types. No power supply is required for operation and they can handle high current loads. Since mechanical switches use dry contacts, they are not polarized or voltage sensitive and are immune to many electrical imperfections such as electrical noise, radio frequency interference, leakage current, and voltage drop. Often these switches are self-contained with NC or NO contacts as required.

Proximity Valve Limit Switches

A proximity switch is a position switch that can be operated without direct mechanical contact with moving parts. Its main function is to detect the presence or absence of an object or to detect its position. Proximity switches are categorized as NPN or PNP-type switches.

Proximity switches have the following characteristics:

1. non-contact detection: does not need to be in direct contact with the object to be detected, avoiding mechanical wear and collision.

2. rapid response: can quickly detect the proximity of the object and output the corresponding signal.

3. High stability: less affected by environmental factors, with high stability and reliability.

4. Long life: relatively long service life, not easy to damage.

5. Convenient installation: can be conveniently installed in a variety of equipment and systems.

Inductive proximity switch:

Composed of an inductive coil capacitor and transistor to form an oscillator and produce an alternating magnetic field, when a metal object close to this magnetic field produces eddy currents in the body of the metal object, which will lead to the oscillation stop, and this change is amplified and processed by the posterior pole to be converted into a transistor switching signal output.

Features:: good anti-interference performance, high switching frequency; can only sense metal.

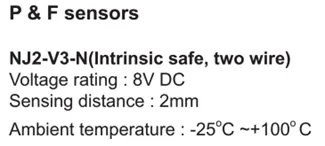

Common inductive proximity switches

Magnetic inductive proximity switches:

Magnetic inductive switches are divided into reed switches, magnetic attraction switches, and Hall switches.

Tongue reed switch: when the magnetic object moves closer the tongue reed closes so that the switch’s internal circuit state changes.

Magnetic attraction switches: Magnetic attraction switches are switches that react to ferrous metals or magnetic targets when they enter the sensing range of the switch.

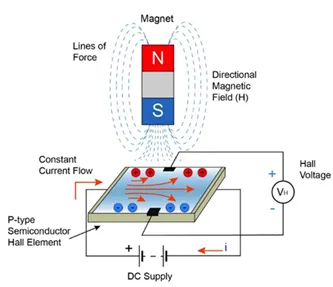

Hall Switch: When a magnetic object moves close to the Hall switch, the Hall element on the detection surface of the switch changes the state of the switch’s internal circuit due to the Hall effect.

When selecting a proximity switch, the following factors need to be considered:

1. Detection distance: Select the appropriate detection distance according to the actual demand.

2. Working environment: Consider the effect of temperature, humidity, dust, and other factors on the switch.

3. object material: different types of proximity switches have certain requirements on the material of the detected object.

4. output signal: choose the suitable output signal type according to the requirements of the control system.