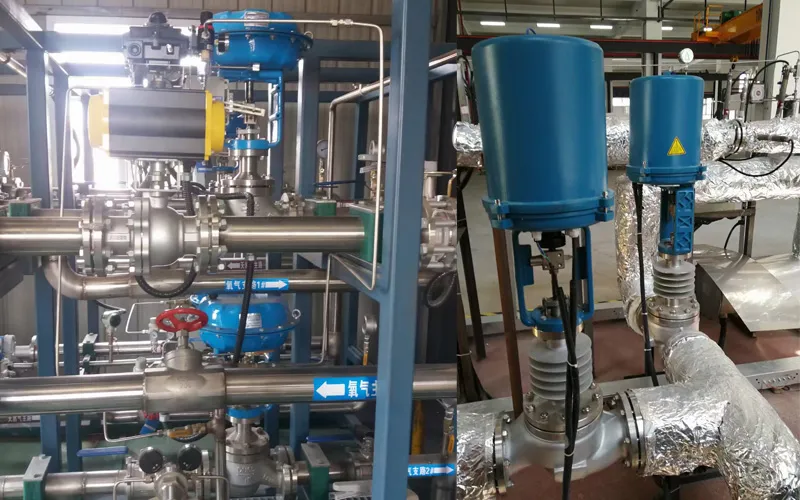

Pneumatic Actuator vs Electric Actuator

Overview of Pneumatic Actuator vs Electric Actuator

Valve automation is a crucial component of modern industry, handling tasks from pipeline flow control to aircraft maneuvering. Two main players dominate this field: pneumatic and electric actuators. Both bring unique attributes to the table and understanding these differences is paramount in making the aptest control system choice.

Technical Performance of Pneumatic Actuator vs Electric Actuator

Advantages of Pneumatic Actuators

- Large load, suitable for applications with high torque output.

- Quick action and quick reaction.

- It has good adaptability to the working environment, especially in harsh working environments such as flammable, explosive, dusty, strong magnetism, radiation, and vibration, and is superior to hydraulic, electronic, and electrical controls.

- The motor is easily damaged when the stroke is blocked or the valve stem is stuck.

Advantages of Electric Actuators

- Compact structure and small size. Compared with pneumatic actuators, the structure of electric actuators is relatively simple. A basic electronic system includes an actuator, a three-position DPDT switch, a fuse, and some wires, which is easy to assemble.

- The driving source of electric actuators is very flexible. Generally, vehicle power supply can meet the needs, while pneumatic actuators require an air source and compression driving device.

- Electric actuators have no risk of “air leakage” and are highly reliable, while the compressibility of air makes pneumatic actuators slightly less stable.

- There is no need to install and maintain various pneumatic pipelines.

- The load can be maintained without power, while pneumatic actuators require continuous pressure supply.

- Electric actuators are quieter because no additional pressure device is required. Usually, if the pneumatic actuator is under heavy load, a silencer should be installed.

- In pneumatic devices, it is usually necessary to convert electrical signals into pneumatic signals and then into electrical signals. The transmission speed is slow and it is not suitable for complex circuits with too many component levels.

- Electric actuators are superior in control accuracy.

Summary

- In reality, pneumatic and electric systems are not mutually exclusive. Pneumatic actuators can easily realize rapid linear cyclic motion, have a simple structure, and have convenient maintenance. They can also be used in various harsh working environments, such as explosion-proof requirements, and dusty or humid working conditions. But where forces increase rapidly and precise positioning is required, electric drives with servomotors have advantages. For applications that require precise, synchronous operation, adjustable, and specified positioning programming, electric drives are the best choice. Electric drive systems composed of servo or stepper motors with closed-loop positioning controllers can supplement the deficiencies of pneumatic systems. at.

- Various systems in modern control are becoming more and more complex and sophisticated, and not just one drive control technology can satisfy the various control functions of the system. Electric actuators are mainly used in applications that require precision control. Flexibility requirements in automation equipment are constantly increasing. The same equipment is often required to adapt to the processing needs of workpieces of different sizes. The actuator needs to perform multi-point positioning control, and the actuator must be Precise control or synchronous tracking of operating speed and torque cannot be achieved using traditional pneumatic control, and electric actuators can easily achieve such control. It can be seen that pneumatic actuators are more suitable for simple motion control, while electric actuators are mostly used in precision motion control situations.