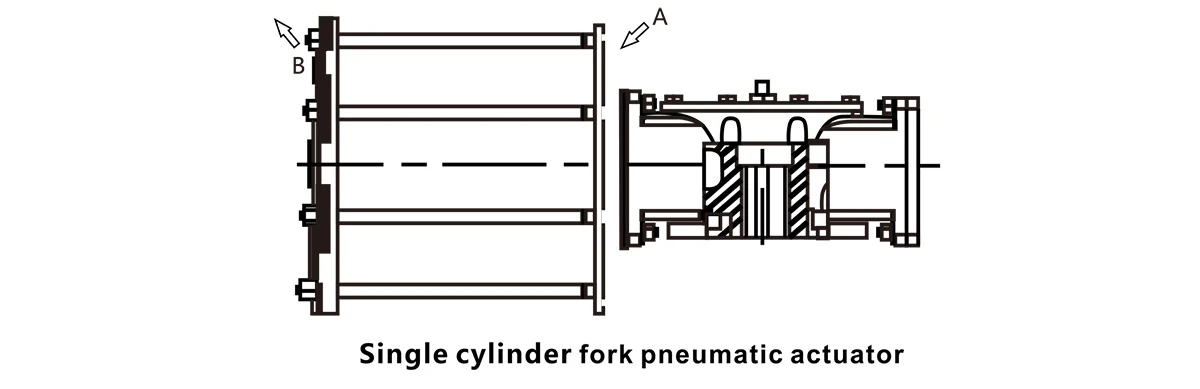

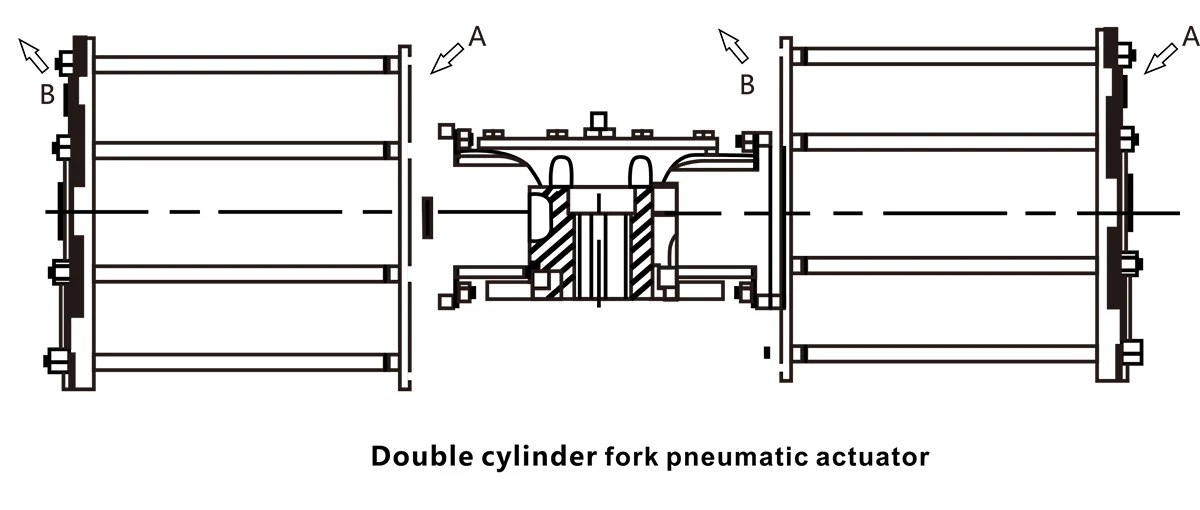

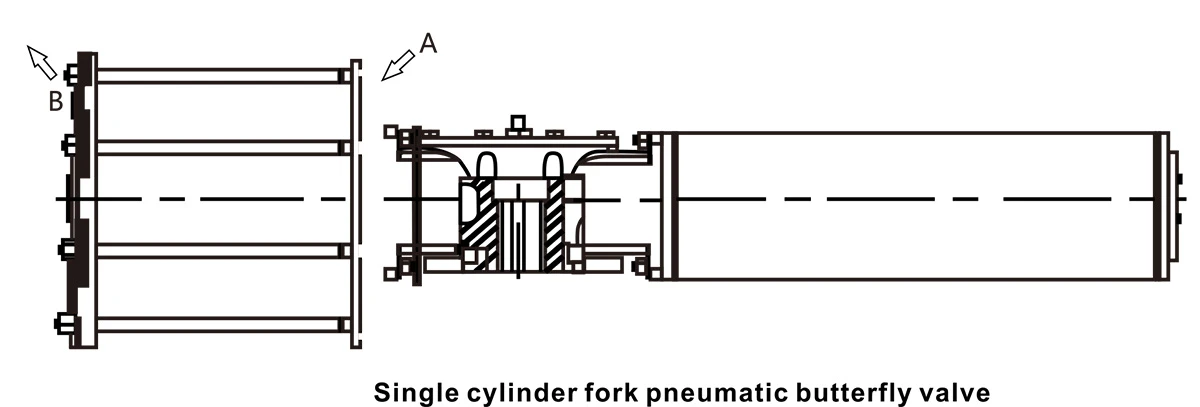

Working Principle of Dual Acting Fork Air Actuator

| When the compressed gas source enters the cylinder from the air hole (A), the gas on the other side of the piston is discharged from the air hole (B) on the other side of the cylinder, and the fork rotates the valve stem to rotate counterclockwise. at which time the valve opens, lf the solenoid valve is reversed, when the compressed gas source enters the cylinder from the air hole (B), the gas on the other side of the piston is discharged from the air hole (A). pushing the piston to move in the opposite direction, and the fork moves the valve stem to rotate clockwise. shut down. | When the single-acting pneumatic control valve is installed in the conveying pipeline, it should pay attention to the normally closed or normally open mode, and the cylinder module and the spring module on both sides of the driving box can be interchanged to realize the mode interchange; when the compressed air is from the right side of the cylinder (A) When the air hole enters, the gas on the left side of the piston is discharged from the (B) air hole, pushing the piston to the outside, driving the fork to rotate counterclockwise, and compressing the spring, at this time opening the valve when the compressed air is from the right side of the cylinder (A) When released, the spring automatically returns to the position and drives the fork to rotate clockwise. The left side of the piston (B) is vented to balance the air pressure to achieve valve closing |

Output Torque of Double Cylinder Double Acting Air Actuator

| Model | Air Source Pressure (Mpa) | |||

| 0.3 | 0.4 | 0.5 | 0.6 | |

| YCG0-200*2 | 1396 | 1861 | 2326 | 2791 |

| YCG1-200*2 | 1646 | 2195 | 2744 | 3293 |

| YCG1-250*2 | 2573 | 3430 | 4288 | 5146 |

| YCG2-250*2 | 2964 | 3952 | 4940 | 5928 |

| YCG2-300*2 | 4268 | 5691 | 7114 | 8537 |

| YCG3-300*2 | 5114 | 6818 | 8523 | 10228 |

| YCG3-350*2 | 6977 | 9303 | 11629 | 13955 |

| YCG4-350*2 | 8912 | 11882 | 14853 | 17824 |

| YCG4-400*2 | 11041 | 14721 | 18401 | 22081 |

| YCG4-450*2 | 14732 | 19643 | 24554 | 29465 |

| YCG4-500*2 | 18188 | 24251 | 30314 | 36377 |

| YCG5-500*2 | 22931 | 30575 | 38219 | 45863 |

| YCG5-550*2 | 27747 | 36996 | 46245 | 55494 |

| YCG5-600*2 | 33022 | 44029 | 55036 | 66043 |

| YCG5-700*2 | 44886 | 59848 | 74810 | 89772 |

| YCG6-600*2 | 53904 | 71872 | 89840 | 107808 |

| YCG6-700*2 | 69324 | 92432 | 115540 | 138648 |

| YCG6-800*2 | 74335 | 99114 | 123892 | 148670 |

| YCG7-800*2 | 86700 | 115600 | 144500 | 173400 |

| YCG7900*2 | 95700 | 127600 | 159500 | 191400 |

| YCG8-800*2 | 99452 | 132603 | 165754 | 198905 |

| YCG8-900*2 | 110682 | 147576 | 184470 | 221364 |

| YCG9-800*2 | 118061 | 157414 | 196768 | 236122 |

| YCG9-900*2 | 149422 | 199229 | 249036 | 298843 |

| YCG9-1000*2 | 184464 | 245952 | 307440 | 368928 |

Output Torque of Single Cylinder Double Acting Air Actuator

| Model | Air Source Pressure (Mpa) | ||||

| 0.3 | 0.4 | 0.5 | 0.6 | 0.7 | |

| YCG0-200DA | 698 | 884 | 1163 | 1396 | 1628 |

| YCG0-250DA | 1090 | 1454 | 1817 | 2182 | 2544 |

| YCG1-250DA | 1286 | 1715 | 2144 | 2572 | 3001 |

| YCG1-300DA | 1852 | 2470 | 3087 | 3705 | 4322 |

| YCG2-300DA | 2134 | 2845 | 3557 | 4268 | 4980 |

| YCG2-350DA | 2905 | 3873 | 4841 | 5810 | 6778 |

| YCG2-400DA | 3794 | 5059 | 6323 | 7588 | 8853 |

| YCG3-400DA | 4556 | 6075 | 7594 | 9113 | 10632 |

| YCG3-450DA | 5767 | 7689 | 9612 | 11534 | 13456 |

| YCG4-450DA | 7366 | 9821 | 12277 | 14732 | 17188 |

| YCG4-500DA | 9094 | 12125 | 15157 | 18188 | 21220 |

| YCG4-600DA | 13095 | 17461 | 21826 | 26191 | 30557 |

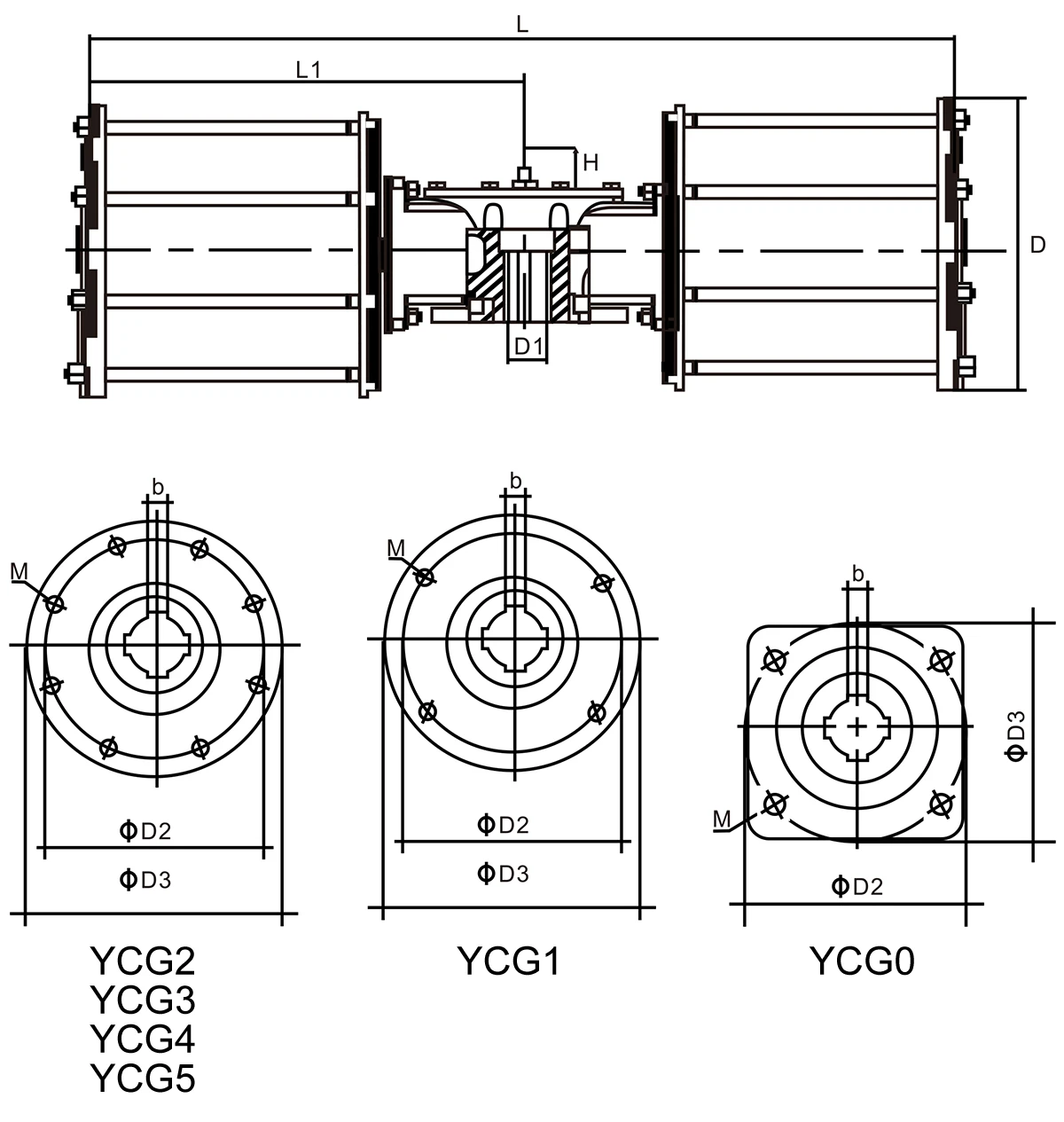

Dimension of Double Cylinder Double Acting Air Actuator

| Model | L | L1 | D | D1 | D2 | D3 | H | b | M | Nm | Air Connection |

| YCG0-200*2 | 774 | 387 | 260 | 30 | 140 | 180 | 30 | 10 | 4-M16 | 2326 | G1/4″ |

| YCG1-200*2 | 948 | 474 | 260 | 40 | 140 | 180 | 30 | 10 | 4-M16 | 2744 | G1/4 |

| YCG1-250*2 | 948 | 474 | 320 | 40 | 165 | 220 | 30 | 12 | 4-M20 | 4288 | G1/4 |

| YCG2-250*2 | 1050 | 525 | 320 | 50 | 165 | 220 | 30 | 12 | 4-M20 | 4940 | G1/4 |

| YCG2-300*2 | 1050 | 525 | 380 | 50 | 200 | 247 | 30 | 14 | 8-M16 | 7114 | G3/8 |

| YCG3-300*2 | 1200 | 600 | 380 | 50 | 200 | 247 | 30 | 14 | 8-M16 | 11629 | G3/8 |

| YCG3-350*2 | 1200 | 600 | 430 | 60 | 200 | 247 | 30 | 14 | 8-M16 | 11629 | G3/8 |

Advantages Of Heavy-Duty Air Actuator

Optimization Design

High Strength, Compact

Manual Override Options

Diversity Control

Wear And Corrosion Resistance

Water Ingress Protection

Universal Standard size

Optimization Design

YCG Series Heavy-Duty Air Actuator adopts the latest structural design scheme, which enables the combination of a transmission module, cylinder module, spring module, and manual control module. lt has good expansion, single action, double action, and other combinations. The program effectively reduces storage costs and shortens the lead time.

High Strength, Compact

The transmission module is placed in the center of the whole machine. The box module is made of cast steel and precision machined by high-precision CNC to ensure sufficient strength, compactness, and reliability. lt outputs the best torque for piston and transmission components. Provide full-time climate and space protection.

Manual Override Options

YCG Series Heavy-Duty Pneumatic Drive uses lateral independent manual devices which are important components of valves or actuators. YUECHI automation has a variety of manual operation methods to meet different working conditions. such as screws, gears, clutch gears, hydraulic manuals, and so on.

Diverisity Control

YUECHI Automatic Control has extensive experience in pneumatic control. Pneumatic control systems are an important part of valves and actuators to meet customer requirements for switching, regulation, and emergency shut-off. The pneumatic system of the YCG Series Heavy-Duty Pneumatic Actuator can be mounted in a panel or control box and can be mounted on the actuator or placed separately.

Wear And Corrosion Resistance

YCG Series Scotch Yoke Pneumatic Actuator adopts an excellent surface treatment piston rod, guide rod, and self-lubricating bearing, The guide slider is made of high-performance aviation aluminum material, organic combination, effectively eliminating lateral load, and sliding parts are wear-resistant and stable: the surface of the body is sprayed with high-tech protection, The coating has a PTFE coating on the inner wall to meet the requirements of metallurgy, petrochemical, and sewage treatment.

Water Ingress Protection

YCG Series Heavy-Duty Scotch Yoke Pneumatic Actuators are protected to IP66 and P67. The joints of the components are equipped with high-performance O-rings and gaskets to ensure that external moisture and dust do not act inside the actuator. Stable and reliable, longer service life.

Universal Standard Size

The actuator output accessory implements the NUMAR standard, and the connected valve size standard conforms to the lSO5211 requirement. Conventional common parts such as seals and fasteners are all implemented concerning international standards so that the YCG series actuators have good versatility and maintainability.

Ordering Instructions

To place an order with YUECHI for automotive solutions for valve applications, adhere to the following guidelines:

Valve

Specify the type of valve (e.g., ball valve, globe valve). Provide information on operational pressure. Specify valve size. Indicate the type of sealing (hard-sealed or soft-sealed). Clearly state the media the valve will handle. Specify the operating temperature.

Pneumatic Actuator

Choose between double-acting and spring-return configurations. Specify whether normally closed or normally open options are needed.

Solenoid Valve Type

Indicate whether a double-solenoid or single-solenoid valve is required. Specify the supply voltage. Specify if an explosion-proof type is necessary.

Limited Switches Box Type

Choose between a basic or explosion-proof type.

Valve Positioner Type

Specify the current signal type. Specify the air supply signal type. Indicate if electric-pneumatic converters are required. Specify the desired explosion-proof grade.

Air Filter & Regulator

Specify requirements for the air filter. Specify requirements for the solenoid valve. Specify requirements for the limit switches box.

Manual Gear Operator

Specify if a declutchable worm gear operator is required.

Customized Solutions

Provide details about any specific accessories required from a designated brand.

Once this information is gathered, contact YUECHI’s sales or customer service department to place your order. Ensure all specifications are accurately communicated to receive the most suitable automotive solutions for your valve applications.